Key considerations include:

- Arrange components to ensure safe operation and facilitate easy monitoring, control, and maintenance.

- Design for redundancy in critical components to maintain operation during failures or maintenance.

- Facilitating the flow of power from incoming transmission lines to outgoing distribution feeders.

- Providing flexibility for future expansion and modifications.

- Ensuring compliance with local, national, and international standards and regulations regarding substation design and operation.

Common substation layouts include:

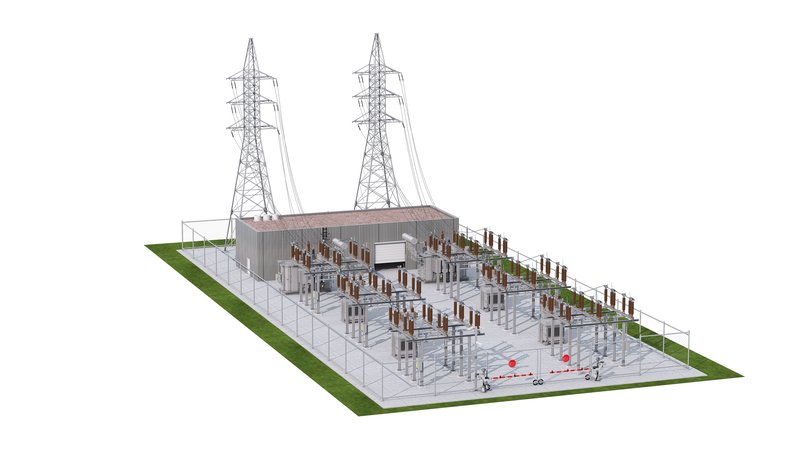

- The incoming overhead lines or cables area

- The high voltage Air Insulated Switchgear (AIS) or Gas Insulated Switchgear (GIS) equipment

- The medium voltage equipment

- The control building and the auxiliary systems areas.